Surfaces with Special Properties - Projects

Fields of Activity

Within the framework of this working group, material systems with special surfaces for tribological systems are investigated, such as those found in artificial knee joints. In such joints, inlays made of UHMWPE run against a metallic friction partner. Conventional metallic materials used for this application are CoCrMo, Ti and Zr alloys.

The latter can be significantly improved by targeted oxidation. The advantages of a ceramic surface (high hardness, low friction) obtained through this oxidation and the metallic base body (high strength and ductility) are thus combined. The friction and wear behavior of these systems can be investigated with the aid of a special knee joint test rig at the chair.

- Thermal oxidation of titanium alloysHide

-

Contact: Daniel Dickes

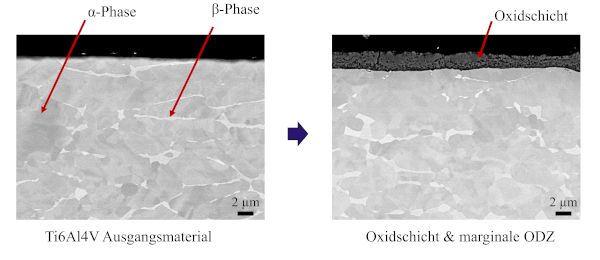

Titanium alloys such as Ti6Al4V are used in many areas, e.g., as lightweight material in the aerospace industry or for medical applications. Titanium alloys form an oxide layer during thermal oxidation. Simultaneously, oxygen diffuses into the substrate, which leads to a hardening in the peripheral zone and can have a positive effect on the tribological properties. Improving the process of thermal oxidation can hence extend the service life of titanium components in applications exposed to wear.

- Oxidation, solid state reduction, oxidation of zirconiumHide

-

Contact: Mike Mosbacher

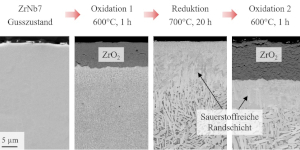

Oxidized zirconium is characterized by the metallic base body and ceramic surface. It shows high wear resistance, high corrosion resistance and excellent biocompatibility. This makes the system very promising for tribological applications in harsh environments such as knee joint prostheses or transmission components.

- Zirconium alloys for tribological applicationsHide

-

Vollständiger Titel:

Development of zirconium alloys for tribological applications and their microstructural and mechanical characterization.

Contact: Michael Reif

Tribological materials with excellent wear - and at the same time very good corrosion behavior and low density - are required for many applications. For example, increasing the service life of artificial joints is of great interest.

Zirconium alloys offer an interesting approach here, since the surface can be transformed into hard, wear- and corrosion-resistant zirconium oxide ceramics by oxidation at elevated temperatures in air, so that the metal can be used for implants. It also has a relatively low density of about 6 g/cm3.

The innovation lies in selecting the alloying elements in such a way that two properties are influenced simultaneously: on the one hand, the strength and hardness of the alloy is increased and, at the same time, the tetragonal oxide phase is formed stably during oxidation. A stronger base material minimizes stresses between the oxide layer and the base material under load. A tetragonal layer adheres better and is more wear resistant. Most zirconium alloys are relatively soft, so that under high point loads there is a risk of the oxide layer flaking off because the base material deforms strongly. In addition, the tetragonal lattice structure initially forms on the zirconium alloys commercially available to date during oxidation in the furnace in air, but this immediately converts to the monoclinic. The tetragonal phase should remain stable in the new alloy mixtures.

- Ceramic coatings in waste incineration and biomass combustion plants as corrosion protection systemHide

-

Contact: Prof. Dr.-Ing. Uwe Glatzel

- Metal Dusting an Ni-Cu-LegierungenHide

-

Vollständiger Titel:

Abhängigkeit des Hochtemperaturangriffs von Kristallorientierung und geringen Mengen thermodynamisch stabiler Oxidbildner

Contact: Hendrik Thielsch

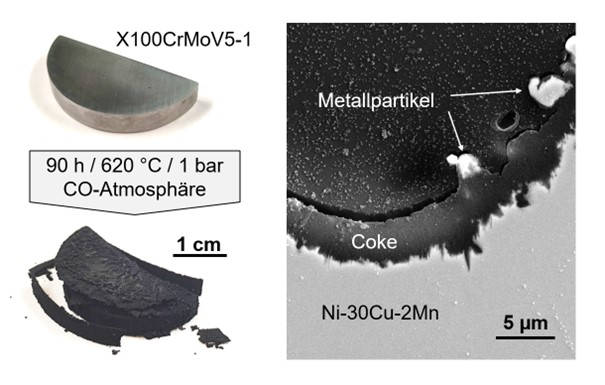

Metal dusting describes an aggressive form of high-temperature corrosion that occurs in industrial applications such as hydrogen and synthesis gas or ammonia production, where it leads to the rapid failure of metallic components. Common iron, nickel and cobalt-based alloys used in reducing, carbon-rich atmospheres in a temperature range of 400-900 °C are affected. Carbon deposited from the atmosphere diffuses into the material and precipitates there as graphite or forms carbides, which causes localised (‘pit corrosion’) or extensive decomposition of the material with the formation of coke as a corrosion product.

When developing resistant alloys, a high proportion of chromium and aluminium is usually added, which forms a passivating oxide layer on the component. The addition of copper can inhibit the dissociation of the gas molecules on the surface and thus the carbon deposition. In this project, the material-side influences of copper content, grain orientation and proportions of stable metal oxides on the mechanisms and kinetics of corrosion attack on nickel-copper alloys are being investigated.